When expertise meets passion

We are passionate about your success. Perfection is our maxim. Whether it’s highly complex or extremely delicate – we find the optimal product for every product. It doesn’t matter if you only require an unfinished part from us or CNC processing including surface treatment. Or if you assign full assembly fitting to us. We offer you everything from a single source.

Your individual requirements are law as far as we are concerned. We develop a precisely accurate and cost-effective solution in discussions with you.

Reliable, tailor-made and precise

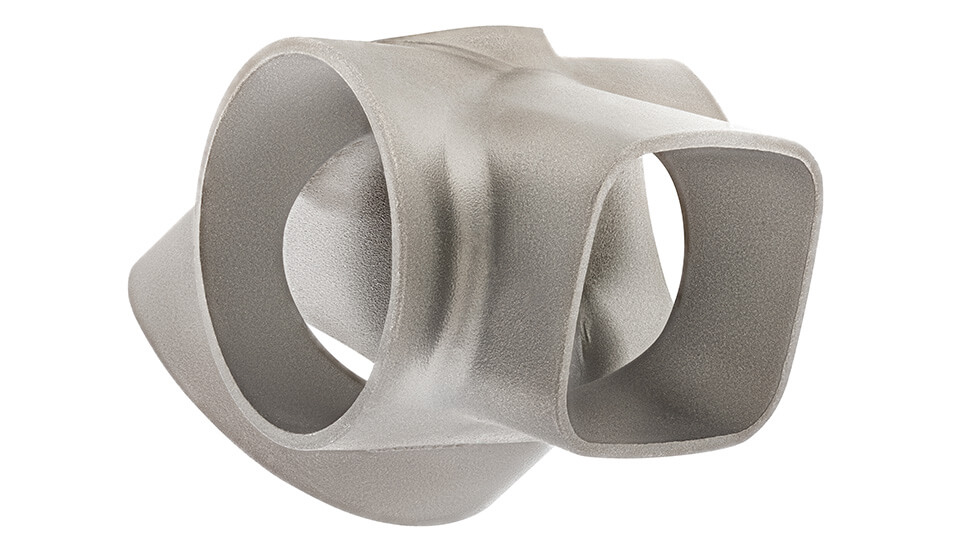

Whether it’s really small or particularly large, weighing just a few grams or sixty kilos, with an incredibly complex shape or simple elegance: Or investment casting parts are as individual as the requirements they are made for. It doesn’t matter if it’s in the ICE, in an Airbus, in the lab or the x-ray machine: Our products are reliable, tailor-made and precise.

Find out more about our services in different sectors.

When you have to really get a move on

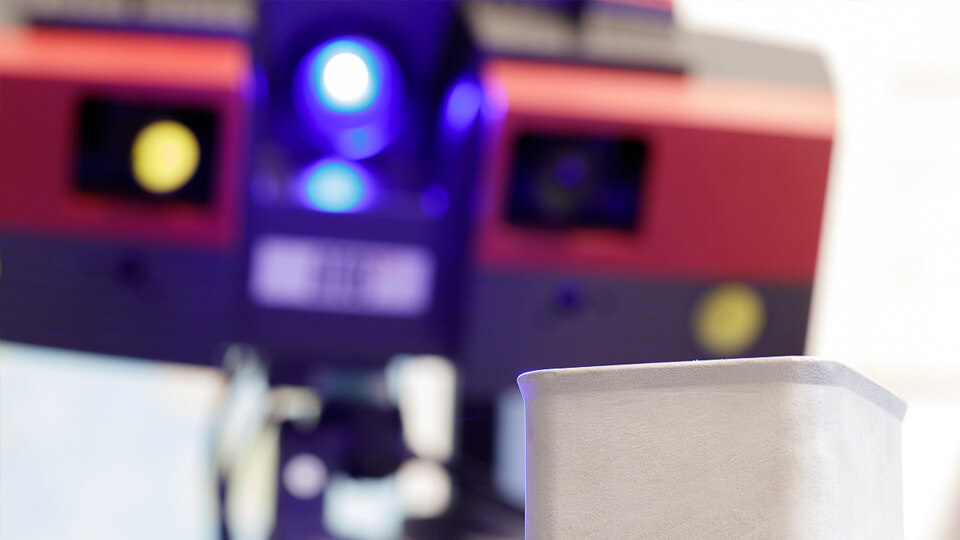

Is speed what you’re after? Then we offer rapid prototyping. Physical materials can be manufactured from digital data with this 3D printing method – at high speed.

Based on 3D construction data, we develop cast part samples and small series components for you in no time. We keep costs low and allow for short delivery times as we manufacture without using any tools.

Another plus is that variants can be easily processed with 3D printing. Rapid prototyping thus gives you a high degree of variability and a great deal of leeway for design.

Versatility is the trump card here – with constant quality

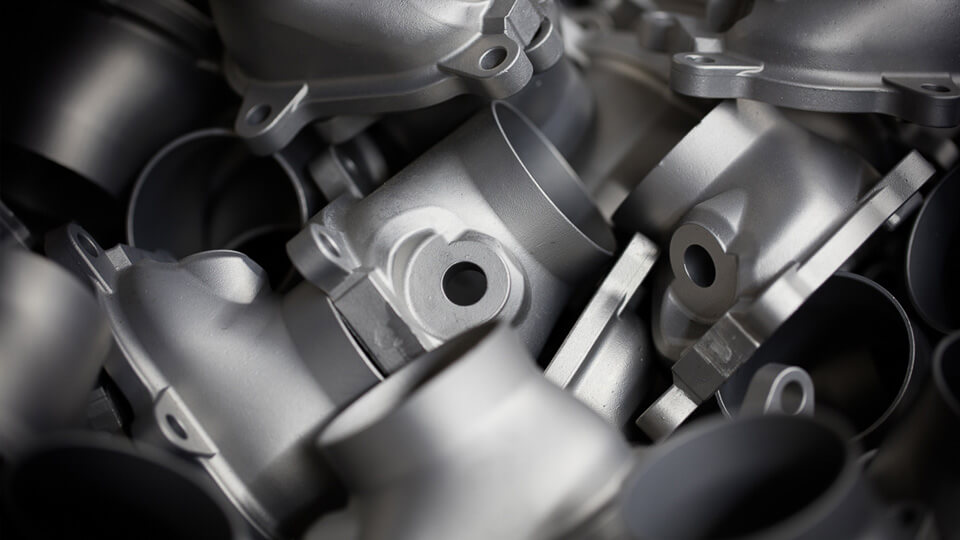

Being innovative is what we do on a daily basis. We aren’t one of the most state-of-the-art customer-focused investment casting plants in Europe for nothing, and we deliver cast parts from an exceptionally large range of standardised and customer-specific types of steel.

Our ready-to-install investment casting parts are manufactured in a lost wax technique without any draft angles. Processing expenditure is low as a result. The result is an exceptionally cost-effective casting method with an extremely high repeatability in terms of dimension and quality – it doesn’t matter if it’s for complex or delicate series shapes.

Why not just get everything from a single source?

We don’t just see ourselves as casters, we also take on various steps in the finishing process. For instance, our services include mechanical, thermal, electro-chemical or physical treatment of your cast part. Just hire us to do further processing. As a system supplier, we offer you all services from a single source, in a straightforward manner.

Every part is top quality

It doesn’t matter if it’s an individual part or series production: We offer top quality, cast part after cast part. By delivering sample parts, we ensure that all steps can be reproduced in the manufacturing process. Thus, the cast part and process workflow are ready for series production. After the sample parts have been approved by the customer, the product can now be produced in a series – even in large quantities (large series).

International quality standards

Quality is our top priority. We work according to international standards with quality management systems DIN EN ISO 9001:2015, DIN EN IST 14001:2015 and VDA 6.1:2016. Optimising manufacturing processes, regulated organisation structures, great relationships with customers and suppliers: We continually make sure of this – and thereby ensure products of the highest quality.

The environment is also close to our hearts. We therefore introduced the environmental management system according to DIN EN ISO 14001 as early as 2004.

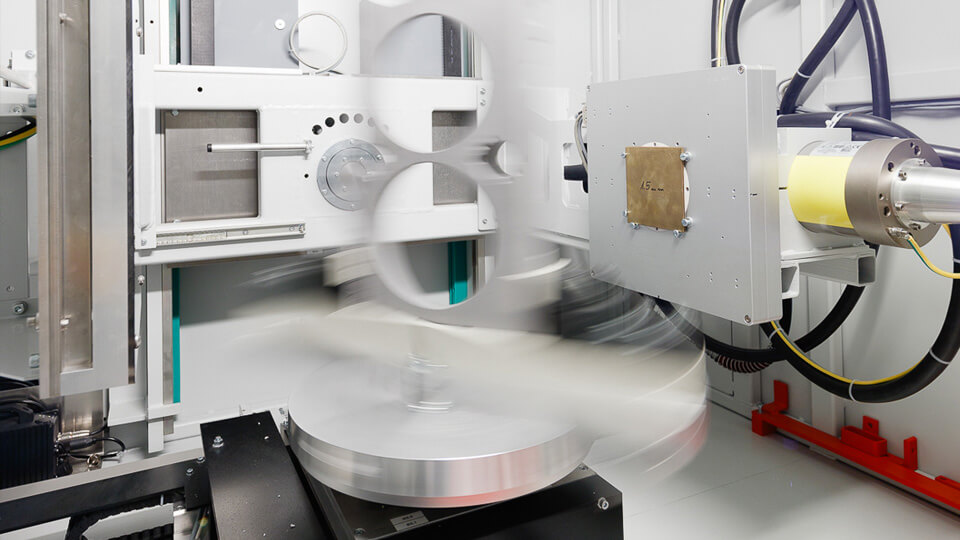

We use the following methods for quality assurance: